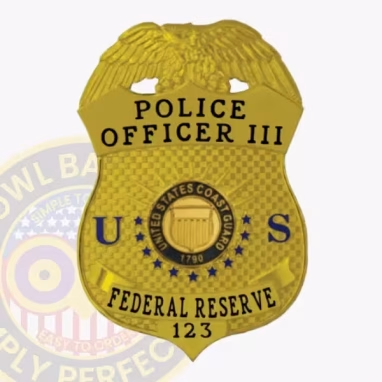

Buy Police Shields: Custom Law Enforcement Shields Online

Professional Police Shield Manufacturing – Order Custom Police Shields, Purchase Officer Shields

Buy authentic police shields through our online design platform. Order custom law enforcement shields, purchase officer identification shields, and buy department shields featuring seals, rank designations, and individual officer information. Our manufacturing process delivers professional police shields for departments, officers, and collectors nationwide.

We believe everyone should have better options

| Compare | Offer Customization | Quality Products | Online Designer | 50% - 80% Bulk Discounts | Easy To Order | Seal Designer | Live Chat 24/7 |

|---|---|---|---|---|---|---|---|

| Owl Badges | |||||||

| Leading Industry Brands | |||||||

| Uniform Companies |

What are they saying about us

Frequently Asked Questions – Shield-Shaped Badge Information

-

What makes shield-shaped designs different from other badge types?

Shield-shaped designs feature raised outer borders with recessed center fields created through specialized die-striking. This dimensional construction differs fundamentally from flat star badges or circular designs. Recessed center ideal for department seal enamel application with raised borders providing protection and traditional appearance.

-

Can you reproduce our department's historical shield design exactly?

Yes, we reproduce historical shield designs from physical examples, photographs, or archived documentation. Process includes dimensional analysis, border profile recreation, seal artwork reproduction, period-correct finishes. Modern manufacturing achieves historical appearance with contemporary quality standards. Consultation ensures authentic reproduction honoring department heritage.

-

What's the difference between narrow and wide shield profiles?

Narrow shields (2.5″-3.0″ width) represent traditional proportions popular historically and continue with East Coast departments. Wide shields (3.0″-3.75″ width) offer contemporary appearance with more space for large seals popular with West Coast agencies. Choice depends on department tradition, aesthetic preference, seal complexity, and regional norms.

-

How much do custom shield outline dies cost?

Custom shield outline dies range $500-$2,000 one-time cost depending on complexity and dimensional requirements. Simple outline variations toward lower end, complex historical reproductions or eagle-top shields toward higher end. Die cost amortized across shield order with per-shield pricing $55-$150 plus volume discounts 30-70%.

-

What production timeline for shields with new dies?

Shield production with new die creation requires 8-12 weeks total. Die design and creation 4-6 weeks, shield manufacturing 4-6 weeks following die completion. Expedited timeline 6-8 weeks possible with rush die creation. Reorders using existing dies complete in 4-6 weeks eliminating die creation phase.

-

Do shield-shaped designs cost more than other badge types?

Shield pricing comparable to other badge types at $55-$150 per shield with 30-70% volume discounts. Custom shield outlines require one-time die costs $500-$2,000 but subsequent reorders no additional die fees. Shield die-striking complexity included in standard pricing. Premium pricing only for highly complex custom outlines or eagle-top variations.

-

Can shields be made in miniature sizes for dress uniforms?

Yes, miniature collar pin versions reproduce full-size shield outlines in 1.0″-1.5″ dimensions for dress uniform collars. Miniature shields maintain same border raise and center recess in reduced scale. Die-striking process adapted for smaller dimensions. Popular for formal occasions and ceremonial uniforms. $40-$75 per miniature pair with volume pricing.

-

What finishes work best for traditional shield designs?

Traditional shields typically specify imitation gold plating for classic law enforcement appearance representing 60% of orders. Silver plating popular for contemporary look. Antique finishes (antique gold or silver) create aged appearance for historical reproductions or traditional departments. Dual-tone finishes combine gold borders with silver centers for distinctive appearance.